INFUSION DRUG DELIVERY ARTICLES

The Future Of Kidney Disease Therapeutics: Bringing Nanomedicine To Nephrology

The Future Of Kidney Disease Therapeutics: Bringing Nanomedicine To Nephrology

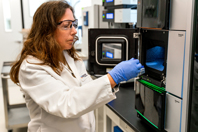

Nanomedicines are solving the drug delivery problem in kidney disease. The next step: bridging the translational gap to advance these technologies into the clinic.

INFUSION DRUG DELIVERY RESOURCES

-

Explore the reasons why one CDMO is expanding its operations to offer flexible bag filling, after being equipped with filling lines for PFS and glass vials (glass or plastic).

-

As IV-administered drugs proliferate, sponsors must understand the associated regulatory requirements, methodologies for useful/required information, and formulations suitable for administration.

-

Healthcare is shifting homeward. With telehealth, connected devices, and user-friendly design, patients and caregivers now deliver hospital-level care safely and effectively outside clinical settings.

-

Explore the rationale behind opting for a contract development organization (CDO) to fulfill organizational requirements and underscore vital considerations for evaluating CDOs to ensure alignment with your project objectives.

-

The increasing prevalence of chronic disorders, growing demand for self-administration, and the increasing demand for minimally invasive surgeries have fueled the growth of the LAI drug delivery market.

-

Demonstrating the compatibility of any material in contact with drug product throughout its lifecycle (manufacture, containment, and delivery) is a necessity for a regulatory submission.

-

Growth in the development of parenteral drugs is driving demand for advanced drug delivery devices such as prefilled syringes, autoinjectors, and pen-injectors, growing segments in fill-finish manufacturing.

INFUSION DRUG DELIVERY SOLUTIONS

-

BD Neopak™ XtraFlow™ Glass Prefillable Syringe solution leverages 8 mm needle length in combination with thin wall cannula to reduce pressure drop and enhance flow.

-

These containers can be delivered with a full line of solutions used in clinical settings, including basic saline, heparin premix, and lidocaine. The chemistry used to produce the container uses neither polyvinyl chloride (PVC) nor the plasticizer DEHP.

-

In recent years, hospitals, clinics, and others have experienced chronic shortages of medical solutions. The Solutions for Life initiative is a billion-dollar investment in meeting nationwide demand for these products.

-

Capabilities that improve efficiency and accelerate development.

B. Braun's OEM Division offers a variety of in-house molding capabilities including injection molding, insert molding and over molding. They own a primary 400,000-square-foot U.S. plant that includes a 16,500-square-foot ISO Class 8 molding facility housing some of B. Braun’s 80 injection molding presses, which range from 55-330 tons.

-

This comprehensive suite of services encompasses the entire spectrum of user research, starting from the conceptualization of study designs to meticulous data analysis and comprehensive reporting.

-

RASR filling and closing machines are designed to treat IV bags. These machines are able to fill single chamber as well as dialysis multi-chambers bags.

-

Examine a NVGD platform that tackles the primary obstacle hindering gene editing therapies: efficient delivery. Utilizing engineered nanoparticles, the platform overcomes limitations associated with payload size.

-

By partnering with Battelle, your organization can reduce risks and save on investment costs, leading to more successful and sustainable outcomes.

-

Learn how our team of scientists, engineers, and human-centered designers, as well as our world-class facilities, empower us to confidently guide your product toward a successful market launch.

INFUSION DRUG DELIVERY NEWS

- Melbourne-Developed Drug Delivery Platform Delivers 'Impressive' Results In International Bowel And Ovarian Cancer Trial

- Race Executes Agreement With Ardena For GMP Manufacturing Of RC220

- Acasti Announces WuXi Clinical As CRO To Conduct STRIVE-ON Pivotal Phase 3 Safety Trial For GTX-104 In aSAH Patients

- Ascendia Pharmaceuticals Develops Novel Nanoemulsion IV Formulation For Clopidogrel That Received IND Approval

- Viridian Therapeutics Announces Partnership With Drug Delivery Innovator Enable Injections

- Scaling Up Capacity, Eitan Medical Opens New Manufacturing Facility Bolstered by Semi-Automated Production Lines