INJECTABLE DRUG DELIVERY ARTICLES

Injecting Cancer Killers: Intratumoral Therapy For Solid Tumors

Injecting Cancer Killers: Intratumoral Therapy For Solid Tumors

Intratumoral injection bypasses the tumor’s physical defenses entirely, killing cancer cells and creating a personalized immune response that destroys solid tumors.

INJECTABLE DRUG DELIVERY RESOURCES

-

Learn how sterile injectable devices are providing safer and more convenient self-injection delivery, leading to positive patient experiences, better therapy adherence, and improved outcomes.

-

Ahead of the first biosimilar Humira product set to launch in 365 days, this article provides a comprehensive run-down of where biosimilar sponsors stand and the key issues ahead of market formation.

-

Determining bioavailable formulation for animal PK, GLP toxicity, first-in-human, and first-in-patient is challenging. Drug delivery systems are usually used for poorly soluble and bioavailable compounds.

-

As the benefits of delivering biologic drugs as part of a combination product platform are realized, this self-administration trend will continue to grow. From a regulatory perspective, the use of a risk-based approach is foundational.

-

The transition of intravenous in-clinic chronic disease therapies to large volume subcutaneous injections in alternate settings has created an evolving roster of new formulations and treatment options.

-

Developing a combination product and seeking a list of tests to complete design verification testing? Review the details for planning, design inputs, design outputs, and design verification.

-

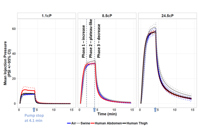

Examine the results of two, two-year studies that indicate good container closure integrity performance that can be achieved with stoppers of a given elastomer, independent of configuration.

INJECTABLE DRUG DELIVERY SOLUTIONS

-

Examine a NVGD platform that tackles the primary obstacle hindering gene editing therapies: efficient delivery. Utilizing engineered nanoparticles, the platform overcomes limitations associated with payload size.

-

Innovative technologies in the pharmaceutical industry are enabling a patient-centric approach in medicine. Auto-injectors provide an easy, convenient drug-delivery system for patient self-administration — improving compliance and dosage accuracy.

-

Rotary filling, stoppering/tip placement/pump inserting and crimping or closing machine for bottles and vials up to 6000 u/h. The system is compatible with RABs or isolator enclosures. The system is able to work with stainless steel or ceramic rotary piston pumps or peristaltic pumps. Systems are available for manual or semi-automatic debagging, manual, semi-automatic or automatic delidding for pre-sterilized glass as well as cleanroom unscrambler’s for ophthalmic containers. Systems are 21 CFR Part 11 and audit trail compatible.

-

A pre-verified delivery platform eliminates redundant testing, simplifies regulatory submissions, and optimizes inventory management, allowing teams to focus on drug-specific performance.

-

This comprehensive suite of services encompasses the entire spectrum of user research, starting from the conceptualization of study designs to meticulous data analysis and comprehensive reporting.

-

Why take the risk of selecting individual components that may not work well together? The West Ready Pack™ containment system, with proven container closure integrity, provides risk mitigation, convenience, and small quantities.

-

AST’s ASEPTiCell® and GENiSYS® systems combine industry-proven technologies such as robotics and isolator-barrier systems to provide flexible pharmaceutical aseptic filling and closing of ready-to-use vials, syringes, and cartridges with a single machine. These innovative platforms use a modular design approach to provide a truly adaptive system with the capabilities and features necessary for cGMP production of clinical and commercial sterile injectable products.

-

Societal specializes in modified-release formulations, including those for high potent and DEA controlled substances.

-

Review the potential of Corning Valor® Glass to optimize the fill/finish process and reduce total cost of quality as well as overall manufacturing cost.

-

Integrated device assembly, labeling, and packaging solutions streamline pharma delivery, ensuring compliance, scalability, and patient-centric design from clinical trials to commercial production.