ORAL DRUG DELIVERY ARTICLES

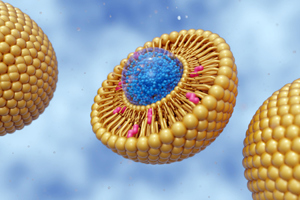

Rethinking Product Development Through Lipid-Based Formulations

Rethinking Product Development Through Lipid-Based Formulations

Optimization of lipid-based drug formulation, when developed with the correct technology, can lead to major product performance enhancements that benefits patients.

ORAL DRUG DELIVERY RESOURCES

-

Drugs have become more lipophilic and complex in structure over time. Innovative strategies are needed to improve the bioavailability of these new drugs.

-

Careful selection of appropriate excipients and delivery technologies is key to the design of modified release (MR) formulations fulfilling specific performance requirements.

-

Explore how utilizing technologies like AI and digital twinning can inform decision-making at the R&D stage and how to optimize the delivery of the final drug product to patients with greener logistics.

-

Explore the application of in vitro flux assays to nanoparticles, with data on how the in vitro permeability apparatus can characterize the membrane flux performance of an API formulated as a nanosuspension.

-

Early-stage development is an iterative process, continuously generating new data and insights to optimize the product based on emerging knowledge.

-

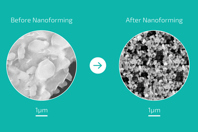

The pharma industry is identifying ways to make processes more sustainable. Learn how nanoparticle engineering technology can both empower sustainability goals and lead to better patient outcomes.

-

A lead compound showed clinical promise but had limited bioavailability owing to low solubility. Learn about the challenges, including the molecular characterization and limited budget, and the structured 3-step approach.

ORAL DRUG DELIVERY SOLUTIONS

-

Multiparticulates enable tailored drug release with improved flexibility, dose accuracy, and patient convenience, leveraging technologies like Diffucaps® for customized profiles including immediate, delayed, extended, and pulsatile delivery.

-

As the number of poorly soluble compounds continues to increase in the industry development pipeline, conventional formulation strategies may not be sufficient to achieve acceptable levels of solubility in the gastrointestinal tract and hence absorption into the systemic circulation.

-

Learn what oral modified-release (MR) dosage forms can offer and why they continue to rise in popularity.

-

Adare Pharma Solutions provides end-to-end CDMO services for oral solid dose drugs, enabling efficient development, manufacturing, and packaging with advanced technologies and global scale.

-

Battelle, a leading nonprofit in applied science and technology, drives innovation in national security, healthcare, environment, and education while managing research labs and advancing critical discoveries.

-

A new six-phase assessment process simplifies regulatory approval for generic drug-device combination products, reducing costs and timelines while maintaining safety, effectiveness, and substitutability with reference-listed drugs.

-

AustinPx offers integrated GMP manufacturing services for oral dosage forms with a full complement of analytical development and testing capabilities.

-

This comprehensive suite of services encompasses the entire spectrum of user research, starting from the conceptualization of study designs to meticulous data analysis and comprehensive reporting.

-

Developing an optimized formulation tailored to your API nanoparticles is critical to unlocking their full potential.

-

Nanoform’s award-winning Controlled Expansion of Supercritical Solutions (CESS®) technology is a bottom-up nanoparticle engineering approach that enables the creation of API nanoparticles and can unlock the full therapeutic potential of small molecule drugs.